Continuous Carbonizing Furnace Exported to The UK

Shuliy Machinery provides customized carbonization solutions and charcoal making machine according to the different production volumes and budgets of our customers. Here is the solution we proposed for a customer from the UK. We recommended the SL-1200 model continuous carbonizing furnace according to the customer’s needs. Nowadays, the charcoal making machine has now arrived and is in operation in the customer’s city.

Details instruction of UK customer

The customer from the UK is involved in charcoal production and his raw material is mainly wood chips and wood shavings. Now his charcoal plant is expanding, so he wanted to upgrade his machine to increase the production capacity, which is expected to be 800 kg per hour. After browsing our website, he was interested in our charring equipment and contacted us.

Considering the small size of the raw material, our sales manager Beco recommended the pyrolysis model continuous charcoal burner to the UK customer. However, due to the customer’s limited budget, Beco also recommended the SL-1200 mini charcoal machine with an output of 1000 kg per hour, which is also a continuous model and can produce charcoal continuously. The output of this machine meets the customer’s needs and the price is within the customer’s budget. So he quickly purchased the machine.

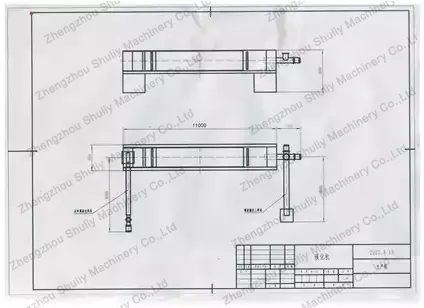

Technical parameter of UK continuous carbonizing furnace

The following data shows the technical parameters of the UK customer’s continuous charcoal making machine.

| Machine Model | SL-1200 |

| Diameter | 11.5*2*1.9m |

| Capacity | 1000kg per hour |

| Power | 25kw |

| Input Size | less than 10cm |

| Carbonization Ratio for Wood | 3-4:1(3-4 t wood:1t charcoal) |

| Carbonization Temperature | 600-800 degrees Celsius |

| Machine Accessories | 6 motors, 2 feedings, 1 discharging, a main motor, and a fan |

Other tips of Uk carbonization plant

- Fuel: 15-20 kg of LPG per day.

Firstly, burn with LPG for 1-1.5 hours, then combustible gas will be produced, no need to add LPG. In addition, the gas produced in the carbonization process can be recycled. - Customers need to prepare a large enough space, the volume of continuous carbonization furnace: length: 22 meters; width: less than 10 meters; height: more than 5 meters.

- Only two workers are needed for the whole process of charcoal making with the charcoal making machine, one is responsible for feeding and sending the wood chips into the conveyor, and the other one is responsible for collecting the finished charcoal chips.

Why did customer purchase our charcoal making machine?

- Support one-to-one customization. We can recommend and customize the charring machine to meet the specific requirements of the customer.

- Professional guidance. Professional engineers and sales team to provide you with better products and at the same time, give you better guidance.

- Thoughtful service. Throughout the service process, our sales managers will respond quickly to customers and promptly reply to their questions about the charcoal carbonizer machine. After the charcoal making machine arrives at your factory, we can arrange online installation guidance or send a technician to visit and help install the carbonization equipment on site.

UK continuous carbonization furnace display

The charcoal manufacturing machine has arrived in the UK nowadays, our customer was pleased that the long journey of the machine did not influence the machine quality. They have used it for their charcoal making businesses.