Horizontal Carbonization Furnace | Charcoal Making Machine for Sale

| Model | WD-HC1300, WD-HC1500, WD-HC1900 |

| Working Method | Batch Type |

| Capacity | 900-3000kg/h |

| Weight | 2500kg-5500kg |

| Brand | Shuliy Machinery |

| Warranty | 12 Months |

You can now ask our project managers for technical details

Shuliy charcoal making machine for sale can produce high-quality charcoal by carbonization technology. The horizontal carbonization furnace is very suitable for charring large materials such as branches, wooden blocks, logs, and biomass briquettes. The carbonized biomass briquettes are very suitable for making barbecue charcoal, so the charcoal making machine is also called a BBQ charcoal making machine.

Compared with other types of carbonization furnaces, the horizontal carbonization furnace has a horizontal design. The raw materials spread over a larger area, heat more evenly, and achieve stable carbonization, avoiding over-burning or incomplete carbonization. At the same time, loading and unloading are easier, which greatly saves labor costs.

This furnace can carbonize 900–3000 kg per batch. According to different capacities, Shuliy offers 3 models. All of them are equipped with a smoke purification system, allowing carbonization to run in an oxygen-free condition without consuming any fuel.

Shuliy has over 20 years of experience in manufacturing carbonization furnaces and more than 10 years of export history. The machines have been shipped to over 50 countries and regions, including El Dorado, Russia, Australia, Tunisia, the UK, and Italy, and have won wide praise from customers.

Raw materials of horizontal carbonization furnace

A horizontal carbonization furnace is one kind of biomass charcoal making machine, which is used to deal with logs, branches, wood chunks, bamboo, coconut shells, trimmings from furniture factories, biomass briquettes and other large pieces of materials. (If you want to crush the material into wood chips below 3cm, you can choose Shuliy continuous carbonization furnace)

Final products of charcoal production machine

The final product is fully carbonized, which can meet the needs of customers.

Advanced design of horizontal carbonization furnace advantages

- The horizontal charring furnace is well insulated and has a double-layer structure inside. There is light insulation, rock wool in the middle of the sandwich, which can always keep the temperature inside the furnace from dissipating.

- The horizontal charring furnace is well sealed. The door of the furnace is sealed with high-temperature rock wool to prevent air from entering, and the operation is safe.

- The charcoal production machine saves fuel. The material will produce a large amount of yellowish combustible gas during the charring process. These combustible gases pass through the pipeline to the combustion area for secondary ignition and combustion, which can save fuel.

- Convenient loading and unloading. A horizontal carbonization furnace with a large capacity, equipped with guide rails and trolleys, which can make full use of the space inside the furnace. It is convenient for operators and reduces their labor intensity.

- Multiple heating options. Compatible with various fuels, including wood, coal, and natural gas, allowing flexible choice based on availability and cost.

- Well-designed furnace door. The round door is made of high-strength heat-resistant steel plate with built-in insulating rock wool for heat insulation and preservation. The lock parts are made of high-temperature alloy steel that does not deform under heat. The furnace edge is equipped with a high-temperature sealing strip to prevent combustible gas leakage.

Working principle

Ignition and heating

Ignite the external heater or furnace using wood, coal, gas, or recovered carbonization gas as the initial heat source, gradually raising the furnace temperature.

Production and recovery of combustible gas

As the temperature rises, the raw material begins to pyrolyze, producing combustible gases like carbon monoxide, methane, and hydrogen, along with impurities such as wood tar and wood vinegar. Using gas separation and condensation devices, by-products like tar and acetic acid are removed, leaving relatively pure combustible gas.

Gas recycling for self-fueling

The separated combustible gas is sent back to the furnace to burn as a secondary heat source. At this stage, the carbonization process becomes self-sufficient, and no extra external fuel is needed.

Carbonization temperature

When the furnace temperature reaches around 600 ℃, the carbonization reaction enters a stable stage. Open the main furnace gas valve to ensure smooth discharge and recycling of combustible gas, maintaining continuous carbonization.

Structure of a horizontal carbonization furnace

Furnace body

The main chamber where raw materials are loaded and carbonized.

Furnace door

Round, made of heat-resistant steel with insulation, equipped with high-temperature sealing strips and alloy steel locks.

Heating system

External heater or furnace using wood, coal, natural gas, or recovered carbonization gas.

Gas collection and separation system

Collects combustible gases and separates by-products like tar and wood vinegar.

Exhaust and smoke system

Ensures smooth discharge of gases and maintains continuous carbonization.

Insulation layer

Keeps heat inside the furnace for uniform temperature and energy efficiency.

Loading and unloading mechanism

Facilitates easy handling of raw materials and biochar.

Gas recycling system

Sends combustible gas back to the furnace as a secondary heat source.

Process of charcoal making

- First of all, find a flat piece of land and place the horizontal carbonization furnace. Open the door, put the raw materials to be charred into the cart, and push the cart into the charring furnace.

- Next, build a fire with fuel. When the thermometer inside the hardwood charcoal stove rises to 150-200 degrees, it starts to produce combustible gas, and the combustion of combustible gas will provide the heat source for charring; after 5 hours of the charring process, the internal combustible gas is gradually used up, and the flame will become smaller and smaller at this time. After a few hours, the charring will be completed when the combustible gas is completely burned out.

- After the charring is finished, you cannot open the horizontal carbonization furnace directly, because the charcoal inside the furnace is too hot, which will easily cause spontaneous combustion and danger to the staff.

- Use the sprinkler system that comes with the bbq charcoal making machine to pour some water appropriately, or wait until the surface temperature of the furnace drops to below 50 degrees before you can open the door.

Charcoal making machine for sale

| Model | Working Method | Capacity | Weight | Size |

| WD-HC1300 | Batch Type | 900-1200kg/12-14h | 2500kg | 3*1.7*2.2m |

| WD-HC1500 | Batch Type | 1500-2000kg/12-14h | 4000kg | 4.5*1.9*2.3m |

| WD-HC1900 | Batch Type | 2500-3000kg/12-14h | 5500kg | 5*2.3*2.5m |

Note: It takes 12-14 hours for a horizontal charcoal production machine to carbonize a batch of raw materials, and the specific carbonization time will deviate depending on the raw materials.

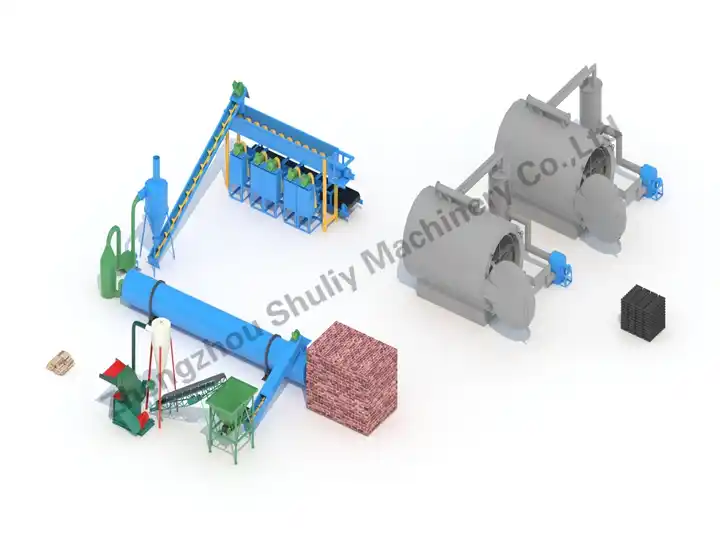

Charcoal production line

The charcoal production line converts wood, bamboo, and other raw materials into high-quality charcoal. The horizontal carbonization furnace is the core unit, thermally decomposing materials under high-temperature, low-oxygen conditions. Combustible gases generated can be recycled to provide self-sustaining heat, ensuring efficient, energy-saving, and environmentally friendly production.

Whether you are processing wood, coconut shells, or other materials, we provide a complete carbonization solution to help you produce high-quality charcoal.

Shipping case

Recently, we successfully shipped a horizontal carbonization furnace to a client in the United Kingdom. The client uses it for a small-scale charcoal production project, requiring high carbonization efficiency and quality. We customized the furnace with high-sealing doors, high-temperature alloy locks, and a combustible gas recovery system to ensure uniform heat distribution and thorough carbonization. The equipment was securely packed in reinforced export wooden crates for safe delivery. Upon arrival, the client reported stable performance and efficient operation, fully meeting their production needs.