Rice Husk Charcoal Making Machine | Rice Hull Carbonizer

| Brand | Shuliy |

| Raw materials | Rice husk |

| Working method | Continuous |

| Capacity | 500-3000kg |

| Warranty | 12 Months |

| After Warranty Service | Video Technical Support, Online Support, Field Maintenance and Repair Service |

You can now ask our project managers for technical details

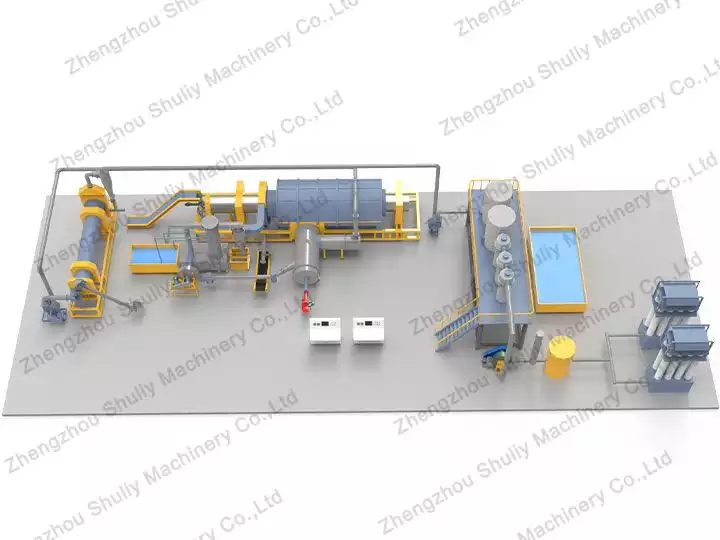

Rice husk charcoal making machine is a piece of popular equipment for producing carbonized rice husk. carbonized rice hull is a new energy source to provide heat for industry or other equipment and is an alternative to traditional energy sources. Shuliy Machinery offers two types of rice husk charring machines, including and continuous type. With the increasing lack of energy sources such as oil, the market for rice husk charcoal as an alternative energy source will continue to grow, and this is the time to invest in a rice husk charcoal making machine to seize the market opportunity and create substantial profits.

Rice husk charcoal making machine for sale

Shuliy group provides two different rice husk carbonization furnaces for customers, both of their working methods is continuous. They are durable and environmentally friendly. In addition, the machine can be applied to carbonized wood chips, coconut shells, or other materials. Tell us the raw materials you need to carbonize and we will give you customized service.

| Model | SL-0812 | SL-1015 | SL-1218 | SL-1320 |

| Hourly Feeding Capacity | 500kg | 0.8-1 Tons | 1.5-2Tons | 2.5-3Tons |

| Working Method | Continuous carbonizing | |||

| Reactor Size | 800mm | 1000mm | 1300mm | 1700mm |

| Heating Materials | Charcoal, wood, diesel, natural gas, LPG, biomass pellets, etc. | |||

| Total Power | 40kw/h | 55kw/h | 60kw/h | 72kw/h |

| Floor Area (L*W*H) | 30m*15m*7m | 35*15*7m | 45*15*10m | 50*15*10m |

| Operating Pressure | Constant Pressure | Constant Pressure | Constant Pressure | Constant Pressure |

| Cooling Method | Recycling Water Cooling |

| Model | SL-CF800 | SL-CF1000 | SL-CF1200 |

| Diameter(mm) | 800 | 1000 | 1200 |

| Capacity(kg/h) | 400-600 | 800-1000 | 1200-1500 |

| Main Power(kw) | 18.5 | 18.5 | 20 |

| Carbonization Temperature(℃) | 500-800 | 500-800 | 500-800 |

| Fan Power(kw) | 5.5 | 5.5 | 5.5 |

Rice hull carbonizer design

Continuous charcoal machine

This rice husk charcoal making machine mainly includes spiral feed, flat feed, main machine, condensing discharge, flame head, combustion pool, purification equipment, power distribution cabinet, etc. The machine is mainly divided into three working areas, which are preheating area, high temperature charring area and cooling area.

Burning pool ignition head

The number of ignition heads varies from model to model, for example, SL-CF1200 model has 18 ignition heads in total. We use them as ignition devices when choosing LPG as the heat source.

Combustion cell

Internal structure of combustion cell

It is made of 4mm thick Q235 steel and 5cm thick high-temperature rock wool, which has good heat insulation and ensures the charring effect.

Design inside the rice husk carbonizer

The rice husk charcoal making machine adopts a 310s stainless steel plate and rock wool, which improves the sealing and heat preservation.

Newest type continuous carbonizing furnace

FAQ of rice husk charcoal making machine

Are there any requirements for rice husk?

The moisture content of raw materials needs to be less than 20%. If the moisture content is high, it needs to be dried in advance with drying equipment.

Can this equipment use peanut shells to make charcoal?

Of course, any material below 10 centimeters is acceptable, such as peanut shells, corn cobs, sorghum stalks, coconut shells, sugarcane bagasse, sawdust, etc.

Do the by-products of combustion cause pollution?

The wood tar and wood vinegar produced by our equipment have anti-burning equipment, which will burn the wood tar and wood vinegar without causing pollution.

Rice hull charcoal making process

- After turning on the rice husk charcoal making machine, the machine is lit with liquefied petroleum gas (LPG). The machine needs to be preheated for about 1 hour and it takes 20-30kg of LPG to ignite once.(The whole process only needs to ignite LPG once)

- When the temperature in the preheating zone reaches 280°-330°, put in raw materials such as rice husk and wood chips.

- Ignite the combustion chamber. After charring for 10-20 minutes, observe the combustion chamber. If combustible gas is produced, turn off the burner and use these gases as fuel, no more LPG.

- As the carbonized rice husk is too hot, it needs to be cooled before unloading. The carbonizing furnace is equipped with a double condenser to help cool the rice husk charcoal.

Why choose Shuliy rice husk charcoal making machine?

Shuliy charcoal machine produces excellent quality rice husk charcoal. After experiments in the factory, it is found that these rice husk charcoal will become granular black solid after being crushed by hand and will not be kneaded into dough or sandy. Some of the rice husk charcoal sold in the market will turn into ash when rubbed by hand, which is of low quality and will have a bad effect on the steel when used in steel making.

Use of carbonized rice hull

- Charred rice husk can be used in industrial production and is an excellent material for providing heat for steel and iron production. Using charred rice hulls can reduce energy consumption and is cost-effective.

- In agriculture, some investors use the final rice husk charcoal as a raw material for fertilizer and soil conditioner. Carbonized rice hulls with Ph value above 7.0 can neutralize acidic soil and avoid soil acidification. In addition, mixing carbonized rice hulls into the medium can make sandy soil more water-retentive and help plants grow.

- There are also many customers who reprocess carbonized rice hulls by grinding them into powder and adding binders to make various shapes of charcoal blocks that can be used for home heating and barbecue charcoal, etc.