Sewage Sludge Carbonization Machine | Sewage Sludge Treatment Plant

| Brand | Shuliy |

| Raw materials | Sewage sludge, printing and dyeing sludge |

| Capacity | 500kg-3000kg |

| Working method | Continuous carbonizing |

| Total power | 40-72kw/h |

| Warranty | 12 Months |

| After Warranty Service | Video Technical Support, Online Support, Field Maintenance and Repair Service |

| Best sell countries | Japan, Germany |

You can now ask our project managers for technical details

Sludge carbonization technology has a high application value, not only for the effective treatment of sludge but also for obtaining a useful value of charcoal. Shuliy machinery has a professional sewage sludge carbonization machine, which is an efficient and environmentally friendly treatment of sewage sludge. In addition, we offer a wide range of options for configuration and installation services, so please contact us if you have a need.

Raw materials of sewage sludge carbonization machine

The sewage sludge carbonization machine can carbonize sewage sludge, municipal sludge, printing and dyeing sludge, industrial sludge and so on, the size of solid materials should be less than 3mm. Moreover, the machine can also carbonize coconut shells, bamboo, and other biomass waste.

Sewage sludge carbonization process

- Dry the raw material. When the moisture exceeds 15%, a dryer should be used to improve the final carbonation efficiency. The sewage sludge is fed to the dryer via a belt conveyor. By preheating for a period of time, the sewage sludge can remove excess moisture in a short time, shortening the carbonization time and improving the carbonization efficiency.

- The dried sludge is conveyed to the carbonization mainframe by a belt conveyor. Through high-temperature carbonization of 300-600℃ to produce sewage sludge charcoal.

- The finished product is cooled down by a water-cooling device and discharged in the full seal, the final charcoal temperature is low, about 30 degrees Celsius, which will not cause burning.

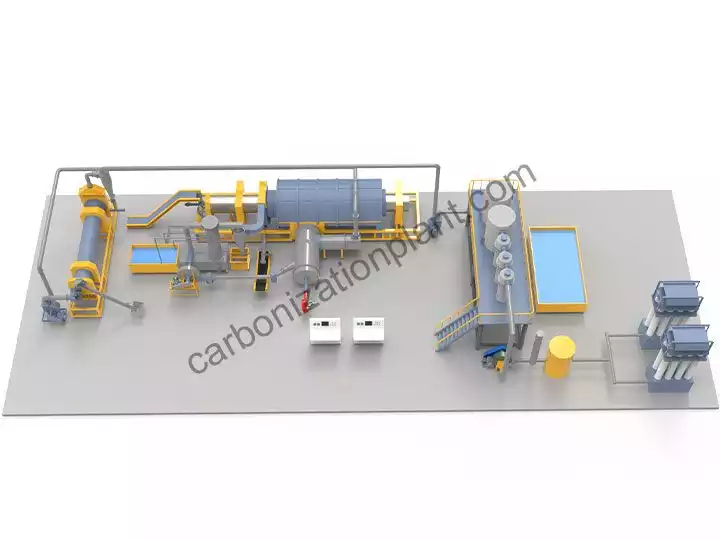

3D video of carbonization plant

The video shows the complete working process of the sewage sludge carbonization plant, the raw materials can be wood chips, sawdust, biomass waste and sewage sludge.

Advantages of sewage sludge carbonization plant

- The sewage sludge carbonization plant is modularized for quick assembly and commissioning.

- The machine adopts advanced automation technology to save labor cost.

- The machine adopts big brand Siemens PLC S7-1500 controller or Modbus control, with long service life.

- The sewage sludge carbonization machine has a highly reliable IOT physical network control system, which is convenient for data acquisition and processing.

Sludge carbonation technology principle

Compared with treatment methods such as drying or direct incineration, sludge carbonization technology has the characteristics of high energy consumption, high carbon content in residual products, and large calorific value, which is very suitable for urban sludge treatment. The high application effect of sludge carbonization technology is mainly because the technology can use high temperature to remove the moisture in the sludge during the application process, and the proportion of carbon in the sludge is greatly increased. Under the action of dry distillation and pyrolysis, organic matter is converted into water vapor without condensation of gas and carbon.

Parameters of sewage sludge carbonization machine

| Model | SL-0812 | SL-1015 | SL-1218 | SL-1320 |

| Hourly Feeding Capacity | 500kg | 0.8-1 Tons | 1.5-2Tons | 2.5-3Tons |

| Working Method | continuous carbonizing | |||

| Reactor Size | 800mm | 1000mm | 1300mm | 1700mm |

| Heating Materials | Charcoal, wood, diesel, natural gas, LPG, biomass pellets, etc. | |||

| Total Power | 40kw/h | 55kw/h | 60kw/h | 72kw/h |

| Floor Area (L*W*H) | 30m*15m*7m | 35*15*7m | 45*15*10m | 50*15*10m |

| Operating Pressure | Constant Pressure | Constant Pressure | Constant Pressure | Constant Pressure |

| Cooling Method | Recycling Water Cooling |

Installation requirements of sewage sludge carbonization plant

Raw material requirements

Calorific value ‘ 10 MJ/kg OS ( raw substance )

DS ‘ 75% DS (dry matter)

Material size ‘ 30 mm

Personnel requirements

Due to the complexity of the process and the sludge carbonization process in large continuous carbonization plants, operators need to have relevant experience in operating the equipment and they also need to have the ability to handle unexpected situations.

Connection requirements

Electricity (380V, 3 phase) , Natural gas (CNG, LPG) 100 mbar, Water + waste water, Nitrogen and compressed air, Internet

The foundation needs to have a load capacity of more than 325 kN.

Minimum space requirement of 150 m² for the carbonization plant.

Policy requirements

Understand local environmental and other policy conditions before charring work.