Bamboo Charcoal Making Machine | Bamboo Carbonization Stove

Bamboo charcoal has many important uses in people’s daily life and has a high market value. Therefore, if you have abundant bamboo resources in your local area, you can choose Shuily bamboo charcoal making machine to make bamboo into bamboo charcoal which can create a great profit margin.

Choose one suitable bamboo carbonization furnace

The size of bamboo is always relatively large, therefore, the horizontal carbonization furnace and hoisting carbonizing stove are the most available choices. However, if you are going to crush the bamboo into small chips, you can choose a continuous charcoal machine.

Horizontal carbonization furnace display

Hoisting carbonization stove display

Shuliy bamboo charcoal making machine for sale

Shuliy group provides batch type and continuous bamboo charcoal machine, customers can choose one machine according to their plant area, bamboo size, budget and other factors.

- The batch charcoal machine is divided into vertical bamboo charcoal making kiln and horizontal bamboo carbonization stove. They are relatively small in size and compact in structure, so they are easy to deliver and install for customers and are suitable for use in small and medium-sized charring plants.

Model |

SL-VC1500 |

SL-HC1300 |

SL-HC1500 |

SL-HC1900 |

Capacity |

2500-3000kg/24 hours |

900-1200kg/12-14h |

1500-2000kg/12-14h |

2500-3000kg/12-14h |

Raw materials |

hard wood, logs, biomass briquettes,wood blocks, bamboo |

|||

Finnal product usage |

BBQ charcoal, household fuels, industrial fuels |

|||

Device size |

1.94m*1,9m*1.9m |

3*1.7*2.2m |

4.5*1.9*2.3m |

5*2.3*2.5m |

Heating materials |

wood, charcoal, coal, wood pellets, etc. |

|||

Weight |

2800kg |

2500kg |

4000kg |

5500kg |

- Shuliy Machinery offers a wide range of 3D charcoal machine design drawings. We show two 3D drawings here, including vertical and horizontal models.

- The continuous bamboo charcoal making machine is divided into small continuous type and pyrolysis continuous type. They can work continuously 24 hours a day to produce large quantities of bamboo charcoal in a short period of time. One thing you should pay attention is the size of the bamboo, the bamboo should be crushed into chips under two cm in advance.

| Model | SL-CF800 | SL-CF1000 | SL-CF1200 | SL-0812 | SL-1015 | SL-1218 | SL-1320 |

| Capacity | 400-600kg | 800-1000kg | 1200-1500kg | 500kg | 800-1000kg | 1500-2000kg | 2500-3000kg |

| Raw materials | wood chips, sawdust, bamboo, rice husk, coconut shells, palm shells, sugarcan bagasse, agricultural straw, domestic waste, industrial sludge, paper mill waste, kitchen waste | ||||||

| Finnal product usage | fuels, raw materials of shisha charcoal and other shaped charcoal briquettes | ||||||

| Heating materials | diesel, natural gas, LPG, biomass, etc. | ||||||

| Power | 24kw/h | 24kw/h | 25.5kw/h | 40kw/h | 55kw/h | 60kw/h | 72kw/h |

| Machine size | 800mm | 1000mm | 1200mm | 35*15*7m | 35*15*7m | 45*15*10m | 50*15*10m |

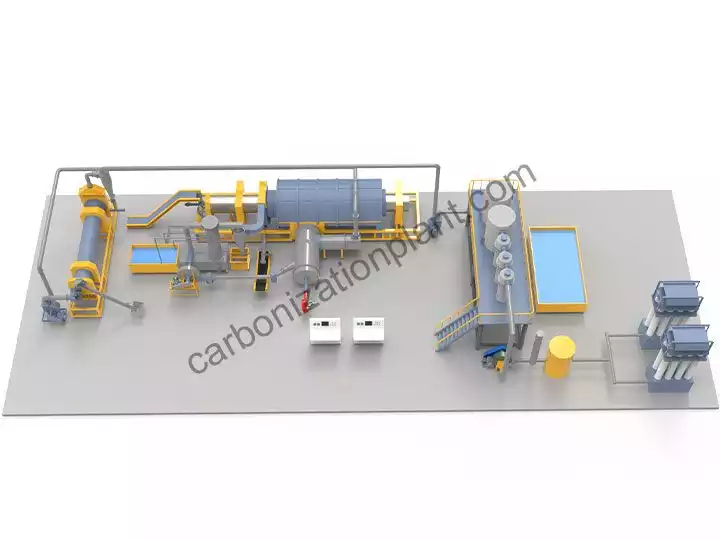

- Shuliy Machinery offers a wide range of 3D charcoal machine design drawings. We show two 3D drawings of continuous models here.

Successful bamboo charcoal making project

Thailand is rich in bamboo resources, and the local wood processing factory purchased our large bamboo charcoal making machine for carbonizing bamboo and other wood.

They chose the SL-C1500 charcoal making machine, which can produce 0.8-1 tons per 8-10 hour. At present, the bamboo carbonization stove has been put into production.

Bamboo charcoal making machine price

The price of the bamboo charcoal making kiln depends on the specific machine you need, different processing methods and different models have different prices. If you need a specific quotation please contact us, our sales manager will send you the quotation as soon as possible.

What is bamboo charcoal?

Bamboo charcoal is a kind of charcoal made from perennial bamboo, which is fired at high temperature. With its loose and porous structure, bamboo charcoal has a strong adsorption capacity and is effective in purifying air and removing odors. Bamboo charcoal has been widely used in daily life and has high economic benefits.

What is bamboo charcoal good for?

- Bamboo charcoal can be used as fuel. Bamboo charcoal is clean and interesting as a fuel for barbecues and picnics. It has a large surface area, generally 300㎡/g for wood charcoal and up to 700㎡/g for bamboo charcoal, and the calorific value is more than 30% of that of wood charcoal.

- Bamboo charcoal fiber is prepared by processing nano-level bamboo charcoal micro powder through high-tech process to produce qualified bamboo charcoal fiber. Now bamboo charcoal fiber fabrics are mainly used in underwear products, shirts, socks, towels and bedding, etc.

- The tiny pores of bamboo charcoal can absorb ethylene gas or various odors produced by refrigerator food and keep the freshness of vegetables, fruits and fish.