Charcoal Making Machine | Biomass Charcoal Carbonization Furnace

| Machine Brand | Shuliy Machinery |

| Model | Vertical, Horizontal, Continuous Type |

| Capacity (kg/h) | 400-3000kg |

| Machine Color | Blue, White, Grey (Support Customization) |

| Raw Materials | Wood, Biomass Waste, Industrial Sludge, Kitchen Waste |

| Warranty | 12 Months |

| After Warranty Service | Video Technical Support, Online Support, Field Maintenance and Repair Service |

You can now ask our project managers for technical details

Charcoal making machine used the most advanced technology to make biomass materials into charcoal. Shuliy group has a wide range of charcoal machines, we can provide customized solutions for each customer according to their raw materials and capacity.

So far, Shuliy charcoal machines have been sold to more than 50 countries and regions around the world such as the UK, USA, Germany, Italy, Turkey, Ukraine, Indonesia, Saudi Arabia, etc. It not only helps customers to utilize biomass waste effectively but also helps them to gain objective profits. When you are in the charcoal manufacturing business, Shuliy machine is undoubtedly a good choice.

Raw materials of charcoal maker machine

To begin with, the biomass waste is the most common material of charcoal carbonization furnace, including sawdust, coconut shells, peanut shells, rice husk, palm kernel shells, sugarcane bagasse, straw.

Secondly, logs, bamboo, and sawdust briquettes are usually carbonized too.

Thirdly, our charcoal making machine can also cope with sewage sludge. The organic matter in the sludge is carbonized and the sewage is evaporated. The nature of the carbonized sludge is similar to activated carbon and can be widely used for adsorption and deodorization, etc. In addition, the charred sludge is non-toxic and odorless and does not cause secondary pollution.

Last, municipal solid waste can be also carbonized by biomass charcoal making machine. Municipal solid waste includes food waste, used plastics, used paper, kitchen waste, and organic waste. The timely disposal of garbage will avoid soil, air, and water pollution.

Final products of charcoal carbonization furnace

- Wood charcoal, coconut charcoal, bamboo charcoal, barbeque charcoal briquettes and so on.

- Wood vinegar and tar. Wood vinegar can improve the soil quality and promote plant growth, and it is a natural fungicide too, which is very environmentally friendly. Wood tar is a raw material for chemical and medicine, also used in medicine, synthetic rubber and metallurgy industries.

Different models of Shuliy charcoal machine

Shuliy Group offers two kinds of wood charcoal making machines, including batch-type charcoal making machine and continuous-type charcoal making machines. The batch type includes vertical carbonizer machine and horizontal carbonizing machine, the continuous type includes the small type and large wood charcoal equipment. When you wanna choose a suitable one, you can consider raw materials, capacity, plant area, and final wood charcoal use.

Batch type charcoal maker machine for sale

Model |

SL-VC1500 |

SL-HC1300 |

SL-HC1500 |

SL-HC1900 |

Working method |

Batch type |

|||

Type |

Vertical |

Horizontal |

||

Capacity |

2500-3000kg/24 hours |

900-1200kg/12-14h |

1500-2000kg/12-14h |

2500-3000kg/12-14h |

Raw materials |

hard wood, logs, biomass briquettes.wood blocks |

|||

Finnal product usage |

BBQ charcoal, household fuels, industrial fuels |

|||

Device size |

1.94m*1,9m*1.9m |

3*1.7*2.2m |

4.5*1.9*2.3m |

5*2.3*2.5m |

Heating materials |

wood, charcoal, coal, wood pellets, etc. |

|||

Weight |

2800kg |

2500kg |

4000kg |

5500kg |

Features of charcoal making machine

For vertical type:

- Each vertical charring furnace can char 50-80kg of materials in one furnace, if the customer has a large output, multiple charring furnaces can work at the same time, and the customer himself can freely decide the number of charring furnaces according to the output, the operation is very flexible and controllable.

- Each vertical charcoal making machine is equipped with extra inner liner, when the charring of one furnace is finished, there is no need to interval time, directly put another full of raw materials into the inner dan to char, so as to increase the efficiency.

For horizontal type:

- Horizontal carbonization furnace has a large output, the minimum output is 900kg of material charred every 12 hours and the maximum output is 3000kg of material charred every small 12 hours.

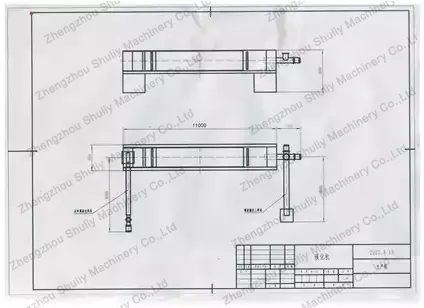

- Horizontal charcoal manufacture machine is equipped with guide rails and trolleys, fill the trolley with materials, push it into the furnace through the guide rails and pull it out directly after the charring is finished, which is very convenient to operate and makes full use of the space inside the furnace.

Continuous charcoal making machine for sale

Model |

SL-CF800 |

SL-CF1000 |

SL-CF1200 |

SL-0812 |

SL-1015 |

SL-1218 |

SL-1320 |

Capacity |

400-600kg |

800-1000kg |

1200-1500kg |

500kg |

800-1000kg |

1500-2000kg |

2500-3000kg |

Raw materials |

wood chips, sawdust, bamboo, rice husk, coconut shells, palm shells, sugarcan bagasse, agricultural straw, domestic waste, industrial sludge, paper mill waste, kitchen waste |

||||||

Finnal product usage |

fuels, raw materials of shisha charcoal and other shaped charcoal briquettes |

||||||

Heating materials |

diesel, natural gas, LPG, biomass pellets, etc. |

||||||

Power |

24kw/h |

24kw/h |

25.5kw/h |

40kw/h |

55kw/h |

60kw/h |

72kw/h |

Machine size |

800mm |

1000mm |

1200mm |

35*15*7m |

35*15*7m |

45*15*10m |

50*15*10m |

Features of countinous charcoal making machine

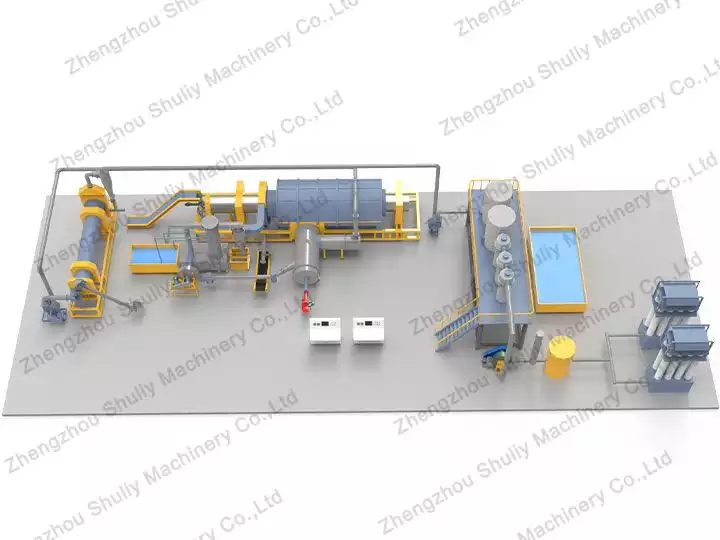

Continuous type charcoal machine is available in two models, each type of charcoal machine is fully continuous type, which can realize synchronization of inlet and outlet. The charcoal making machine can work continuously for 24 hours without interruption. Moreover, the high degree of automation of the continuous charcoal making machine can ensure the long-term stable working time and little labor cost, which can maximize the benefit of customers.

3D video of continuous charcoal making machine working process

Charcoal making machine video

Customized solutions of charcoal manufacturing machine

Continuous charcoal machine exported to England

Shuliy Machinery can provide customized carbonization solutions for different production volumes and budgets of our customers. When you see our website, please contact us and provide us with the raw material you want to carbonize, the production volume and the budget. Here is the solution we proposed to a customer from the UK.

The customer from UK is also engaged in carbon production, mainly charring wood chips, and now wants to upgrade his machine to expand his output, which is expected to be 800 kg per hour. Our sales manager Beco recommended the continuous charring furnace considering the raw material, but due to the customer’s limited budget, Beco also recommended the small charcoal machine model SL-1200, which has an output of 1000 kg per hour, the output of this machine meets the customer’s needs and the price is within the customer’s budget.

Vertical charcoal carbonization furnace sent to Italy

A customer from Italy found us through our website and told us that his small wood charcoal plant needed charred wood with a daily capacity of about 1600 kg. The factory is limited in size but has a requirement for production. Our sales manager Crystal communicated with the customer and recommended the vertical carbonizer machine, which is perfect for charring logs.

Considering the output requirement, Crystal recommended the SL-1300, which can carbonize 500-600 kg every 6-8 hours. Moreover, the charcoal making machine is equipped with two spare inner stoves, which can finish 1500-1800 kg by working non-stop all day. The relatively small size is perfect for this Italian customer’s plant. The customer was satisfied with this carbonizer machine and decided to buy it soon.

Why does charcoal maker machine has a wide potential market?

Applying charcoal machinery is the most environmentally friendly and economical way to deal with biomass waste. With the rapid development of the economy and technology, there is more and more biomass waste, and the traditional way of burning will greatly pollute the environment.

However, the use of advanced charcoal technology to make biomass waste into no charcoal is a viable alternative. Shuliy biomass charcoal making machine will not cause pollution to the environment, and it will also generate economic benefits and bring profits to customers. Therefore more and more people choose to invest in charcoal carbonization furnace.