Best Coconut Shell Charcoal Making Machine

| Brand | Shuliy |

| Raw materials | Coconut shells |

| Working method | Batch or continuous |

| Capacity | 500kg-3000kg |

| Warranty | 12 Months |

| After Warranty Service | Video Technical Support, Online Support, Field Maintenance and Repair Service |

| Best selling countries | Indonesia, Philippines, Uganda |

You can now ask our project managers for technical details

Shuliy coconut shell charcoal making machine for sale is competitive, we can provide many different types of machine according to your personal situation. The process of making charcoal does not cause environmental problems to the environment, and the final product will create a big profit for customers.

Raw materials and final products

Used coconut shells are everywhere, and if the discarded coconut shells are thrown away or burned, then they are not fully utilized. However, making charcoal from coconut shells can increase its commercial value. The final coconut shell charcoal can be a high-quality raw material for making barbecue charcoal and hookah charcoal.

Technical data of coconut shell charcoal making machine

| Model | SL-0812 | SL-1015 | SL-1218 | SL-1320 |

| Hourly Feeding Capacity | 500kg | 0.8-1 Tons | 1.5-2Tons | 2.5-3Tons |

| Working Method | continuous carbonizing | |||

| Reactor Size | 800mm | 1000mm | 1300mm | 1700mm |

| Heating Materials | Charcoal, wood, diesel, natural gas, LPG, biomass pellets, etc. | |||

| Total Power | 40kw/h | 55kw/h | 60kw/h | 72kw/h |

| Floor Area (L*W*H) | 30m*15m*7m | 35*15*7m | 45*15*10m | 50*15*10m |

| Operating Pressure | Constant Pressure | Constant Pressure | Constant Pressure | Constant Pressure |

| Cooling Method | Recycling Water Cooling |

Shuliy coconut shell charcoal machine for sale

Shuliy group provide four types of coconut charcoal making machine for customers, including two batch types and two continuous types. The batch types are hoisting carbonization furnace and a horizontal one, they are much more suitable for small charcoal plants.

The continuous types are small continuous charcoal machine and pyrolysis charcoal machine. In addition, customers can choose the most suitable charcoal furnace for you according to the size of raw materials, installation, floor space, and automation level. Send us your requirements and we will recommend the right coconut shell charcoal making machine for you.

Hoisting carbonization furnace

- Batch type work, completing a batch of charcoal every 6-8 hours

- Simple operation and easy to learn technology.

- Each vertical charcoal making machine is equipped with extra inner liner to improve charring efficiency

Hoisting carbonization furnace

- Batch type work, completing a batch of charring every 12 hours

- The high temperature rock wool inside the charring furnace ensures the temperature inside the furnace

- The horizontal coconut shell charcoal making machine is equipped with a cart, which is very convenient to operate and has a large capacity.

Continuous charcoal furnace

- The continuous charcoal furnace can work continuously for 24 hours, with high production efficiency and high output.

- The raw material should preferably be below 2cm, so that the charring effect will be good.

- The continuous carbonization furnace realizes the functions of automatic collection of tar and wood vinegar liquid and synchronization of combustible gas circulation.

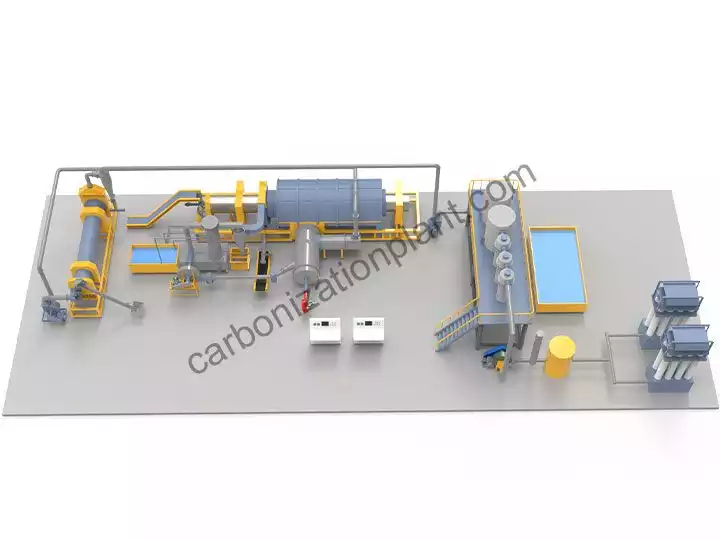

Advanced continuous charcoal machine

- The coconut shell charcoal making machine adopts a continuous type working mode.

- The equipment is very well sealed, there will be no open flame.

- Negative pressure inside the furnace to ensure safe operation, and an explosion-proof device at the end to ensure operational safety.

Coconut shell charcoal making process

Crushing and drying coconut shells are the first step. If the moisture and volume of coconut shells are large, it is necessary to use a dryer and crusher for processing, the size of coconut shells can preferably be less than 2cm, the smaller the size the better the charring effect and the shorter the charring time required.

The coconut shells are automatically fed into the coconut shell carbon manufacturing reactor by a conveyor. After preheating, the coconut shell pyrolysis reaction starts as the temperature rises. When the temperature reaches 300-600 degrees, coconut shell charcoal is made.

Considering the environmental protection aspect, in the coconut shell charcoal making process, the combustible gas produced in the pyrolysis process enters the water seal to remove sulfur and dust. In this process, biogas, tar and wood vinegar liquid are produced. The final coconut shell char will be discharged at the end of the reactor through a water-cooled emitter at a temperature of about 30 degrees Celsius.

Coconut shell charcoal machine price

Every charring equipment of Shuliy Machinery is of high quality and reasonable price. We believe that your investment in our plant is worthwhile. The price of different types of coconut shell charcoal making machine varies. The price is affected by the style of the machine, the size of the output, the price of auxiliary equipment, the price of optional equipment, and the shipping cost. If customers have customized requirements, the cost will be changed. You can consult us and we will provide you with a detailed price list.

Successful coconut charcoal making project

Malaysia is rich in natural resources and the local wood processing plant purchased our large coconut shell charcoal making machine for carbonizing coconut shells and wood. They chose SL-1015 charcoal making machine, which can produce 0.8-1 tons per hour. Now the coconut shell charcoal making machine is in production.

FAQs of coconut shell charcoal making machine

If your raw materials are whole coconut shells with a large volume, we recommend you to choose a vertical or horizontal charring furnace. If you crush the coconut shells beforehand and the raw materials are small pieces of about 2 cm, in this case, we recommend using a continuous carbonization furnace, the specific model can be decided according to your output and factory area.

Each kind of charcoal making machine is excellent, they have their own characteristics. Only the one that meets your actual needs is the best machine.

Shuliy Machinery has exported charcoal making machines to England, Philippines, Malaysia and many other countries.

The coconut shell charcoal can be used widely to manufacture BBQ charcoal, shaped charcoal, shisha charcoal and so on.