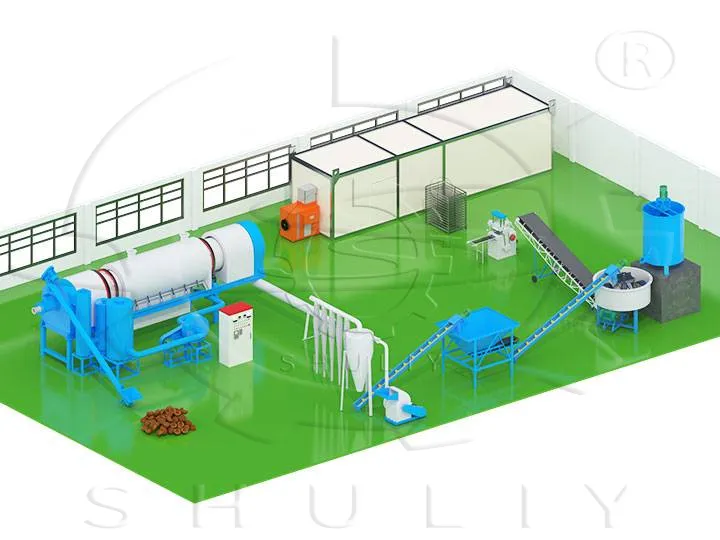

Shisha Charcoal Production Line

| Output Capacity | 200–300 kg/h |

| Raw Materials | Coconut shell, nutshell, wood, other biomass |

| Carbonization Method | Continuous carbonization, high temperature, low oxygen |

| Shaping Method | Briquettes: round, square, or custom patterns |

| Drying Method | Low-temperature drying |

| Main Equipment | Carbonization furnace, crusher, conveyors, roller mill, mixer, briquetting machine, dryer |

| Product Features | Dense, uniform size, stable burn, low ash, odorless |

| Automation Level | Semi-automatic to fully continuous |

| Warranty | 1 year |

| After-Sales Service | Available |

| Spare Parts | Lifetime Supply |

You can now ask our project managers for technical details

With the growing popularity of shisha in the Middle East, Europe, and parts of Africa, Shuliy provides complete shisha charcoal production line solutions, covering the entire process from raw material preparation to carbonization, shaping, and packaging, helping customers produce high-quality shisha charcoal consistently.

Compared to regular fuel charcoal, shisha charcoal requires longer burn time, lower ash content, minimal odor, and greater stability. This has led more manufacturers to adopt standardized, continuous production lines for shisha charcoal.

What Is Shisha Charcoal?

Shisha charcoal is a special type of fuel made specifically for shisha (hookah). Its main purpose is to provide stable and even heat without affecting the flavor of the tobacco. Compared to regular charcoal, shisha charcoal has higher requirements for burn time, ash content, odor, and safety. It is usually produced through standardized manufacturing processes. As the shisha market continues to grow, high-quality, consistent-performance shisha charcoal is becoming an essential product in the industry.

Key Requirements for Shisha Charcoal Production

Shisha charcoal differs from regular wood charcoal, and its production process must focus on several critical aspects:

- Complete and uniform carbonization

- Long burn time with low ash content

- No strong odors or irritating smoke

- Consistent product size for easy use and sale

Because of these requirements, a single machine is often insufficient. A well-designed, integrated production line is essential.

Shisha Charcoal Production Process

Continuous Carbonization

- Pretreated raw materials enter a continuous carbonization furnace, where they are carbonized under high temperature and low oxygen. This ensures uniform carbonization and high fixed carbon content, providing a stable base for further processing.

Charcoal Conveying

- Carbonized charcoal is automatically transported to the next stage via a belt conveyor, reducing manual handling losses and ensuring continuous and safe production.

Charcoal Crushing

- Charcoal is crushed into granules or powder suitable for grinding and shaping. Particle size is controlled to facilitate the next processing steps.

Charcoal Powder Conveying

- Crushed charcoal powder is steadily fed into the grinding system via a screw conveyor, ensuring a uniform and continuous supply while reducing dust.

Grinding and Densification

- Charcoal powder is deeply ground and compressed in a roller mill. This increases density and plasticity, which is key to ensuring briquette strength and stable burning.

Powder Mixing

- The ground powder is thoroughly mixed with binder and water in a horizontal mixer. Uniform mixing helps reduce cracking or crumbling of the finished product.

Mixed Material Conveying

- The prepared mixture is transported to the briquetting machine via a belt conveyor for continuous, automated feeding, improving shaping efficiency.

Shisha Charcoal Briquetting

- The mixture is pressed under high pressure into standard shapes, such as round or square briquettes. The finished briquettes are dense, uniform in size, and ready for drying and packaging.

Shisha Charcoal Drying

- Newly formed briquettes are dried at low temperature to reduce moisture, increase strength, and improve storage stability, preventing breakage during transport or use.

Main Equipment in a Shisha Charcoal Production Line

Continuous Carbonization Furnace

- Model: SL-800

- Operation: Continuous

- Capacity: ~200 kg charcoal/hour

- Heating: LPG or natural gas

- Power: 25 kW

- Drum Thickness: 12 mm

- Description: Carbonizes coconut shells, nutshells, or wood continuously under controlled conditions, ensuring uniform and stable carbonization. This is the core equipment of the shisha charcoal production line.

Belt Conveyor (Charcoal Transport)

- Model: SL-500

- Power: 3 kW

- Belt Width: 500 mm

- Length: 5 m

- Description: Transports carbonized charcoal or blocks to the crushing system, reducing manual handling and maintaining production continuity.

Charcoal Crusher

- Model: SL-500

- Hammer Count: 30

- Power: 22 kW

- Capacity: ~500 kg/hour

- Output Size: 1–10 mm

- Description: Crushes carbonized charcoal into powder or granules suitable for grinding and shaping.

Screw Conveyor

- Model: SL-219

- Power: 3 kW

- Screw Diameter: 219 mm

- Length: 5 m

- Description: Transfers charcoal powder steadily to the mixing system, ensuring continuous and uniform feed.

Wheel Grinder Machine

- Model: SL-1500

- Power: 7.5 kW

- Capacity: 500–800 kg/hour

- Size: 1500 × 1350 mm (H)

- Description: Performs deep grinding and compression of charcoal powder, increasing density and plasticity—key for high-quality shisha charcoal.

Flat Stirring Machine

- Model: SL-1500

- Power: 5.5 kW

- Description: Mixes charcoal powder with binder and water thoroughly, ensuring uniform material for stable briquette formation.

Belt Conveyor (Mixed Material Transport)

- Model: SL-B500

- Belt Width: 500 mm

- Power: 2.2 kW

- Length: 5 m

- Weight: ~500 kg

- Description: Transports mixed charcoal to the shisha charcoal press machine for continuous automatic feeding.

Shisha Charcoal Press Machine

- Pressure: 60 tons

- Power: 13 kW

- Capacity:

- Round: 56 pieces/cycle, 3 cycles/min

- Square: 80 pieces/cycle, 3 cycles/min

- Weight: ~1300 kg

- Size: 2500 × 750 × 2300 mm

- Description: Presses mixed charcoal into standard shisha charcoal shapes, such as round or square briquettes.

Shisha Charcoal Dryer

- Size: 8.8 × 2.3 × 2.5 m

- Capacity: 2–3 tons/batch

- Heating: Coal or gas

- Configuration: 8 trolleys, 80 trays, control cabinet

- Description: Reduces moisture in shisha charcoal, improving strength and stability for storage and transport.

Looking to Buy a Shisha Charcoal Production Line?

Are you struggling with factory layout planning? Worried about paying but not receiving your equipment? Struggling to make an efficient production plan? Do you want to make the best shisha charcoal with limited funds?

If you want to produce high-quality shisha charcoal efficiently, you can contact us. Shuliy provides complete equipment solutions and full support services. Our shisha charcoal production line can make charcoal in different shapes and sizes—round, cubic, or even custom patterns—with an output of 200–300 kg/h, suitable for small and medium-sized businesses.

If you need assistance, get in touch with us today.