Hoisting Carbonization Furnace | Vertical Charcoal Making Kiln

| Model | SL-c1500 |

| Dimension | 1940mm*1900mm*1900mm |

| Outer bladder thickness | 6mm |

| Loading capacity | 2600-3000kg/per 8 hours |

| Weight | 2.8t |

You can now ask our project managers for technical details

A hoisting carbonization furnace is also called a vertical charcoal making kiln, which is a piece of popular equipment for producing biomass charcoal. The carbonized biomass is a good fuel, and there are other by-products, such as wood vinegar liquid, which can also bring profit to customers. Our charcoal-making machine has been exported to Italy, the UK, Guinea, Myanmar, and other countries, and is well-received by customers.

This carbonization furnace has a production capacity of 2,500–3,000 kg every 24 hours. Multiple batches can be carbonized in a single day, greatly shortening the production cycle and improving efficiency. It is the best choice for charcoal production businesses of all sizes.

It can process various raw materials such as logs, wood sticks, large branches, hardwood, coconut shells, nut shells, palm shells, bamboo, straw, wood chips, furniture waste, and sawdust briquettes. Over 90% of customers use it mainly for carbonizing coconut shells and large wood materials.

Hoisting carbonization furnace factory display

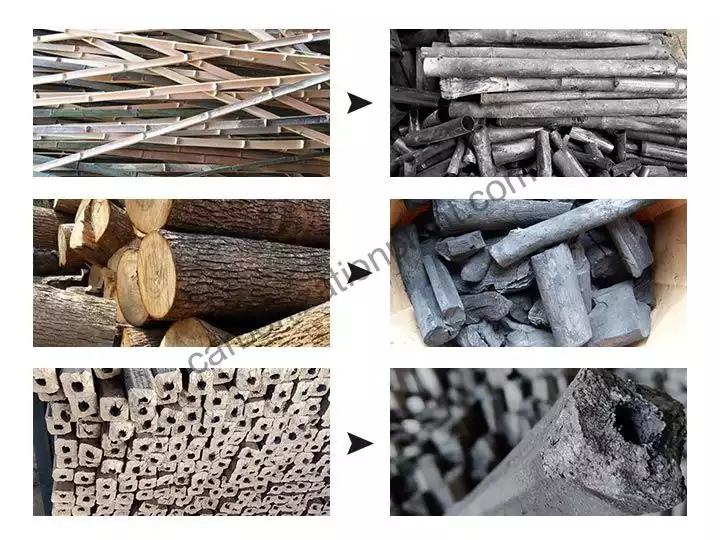

Raw materials of hoisting carbonization furnace

The hoisting charcoal furnace is suitable for large pieces of material, such as wood, logs, wood blocks, hardwood, pine wood, palm wood, coconut shells, palm shells, bamboo, nut shells, straw, wood chips, furniture waste, and sawdust briquettes, wood chunks, wooden furniture trimmings, biomass briquettes, twigs, etc. It is ideal for customers who want to obtain large pieces of charcoal. (If your raw material is less than 3cm, you can choose our continuous carbonization furnace.)

Charcoal effect comparison

Advanced Shuliy vertical charcoal making kiln design

The main structure of the vertical carbonization furnace is the hanger, the outer tank, the inner furnace, the combustion chamber, the vent pipe for combustible gas circulation and the flue gas purification system. The inner furnace is the main carbonization chamber. The shell and inner liner of the vertical charcoal making kiln are made of Q245 steel, and the inner liner has a layer of refractory bricks and high-temperature-resistant rubber.

One furnace body can be equipped with multiple charring inner stoves. No preheating treatment is needed when replacing the charred inner stove. The hanger of the charring furnace is very strong and has a good load-bearing capacity. Carbonization inner chamber. The cooling of the chamber is completely separated from the furnace body, the structure of the equipment is simple and novel, and the operation is very easy.

Overview of structural components

Outer furnace

The outer furnace of the hoisting carbonization furnace is a cylindrical thick-steel structure lined with refractory bricks and insulation, offering good sealing, low heat loss, and high carbonization efficiency. Its exterior is anti-corrosion and heat-resistant, with inspection ports and detachable parts for easy maintenance.

Inner furnace

The core of the hoisting carbonization furnace is the inner chamber, a detachable steel container designed for easy loading and unloading. This compartment is specifically used to hold raw materials for carbonization, such as branches and sawdust briquettes. Typically, the furnace is equipped with three standard inner tanks, which can be used in rotation during the operation cycle to ensure continuous and efficient processing.

Loading box

The loading box simplifies the process of feeding materials into the furnace and efficiently assists in material introduction. In practice, it is commonly used for carbonizing sawdust briquettes with standard shapes, improving loading efficiency and ensuring convenient operation.

Lifting mechanism

Airflow-assisted carbonization furnaces are usually equipped with an automatic lifting system, which allows smooth and effortless movement of internal furnace components, simplifying loading, unloading, and maintenance tasks.

Flue gas purification system

The flue gas purification system is an optional feature for lifting-type charcoal furnaces, designed to filter waste gases produced during carbonization and recover combustible gases. Our purification solutions mainly include conventional flue gas filters and electrostatic flue gas purifiers, ensuring cleaner emissions and improved energy efficiency.

How to make charcoal by lump charcoal making machine?

- The inner stove is lifted into the lump charcoal making machine. The fuel is burned in the combustion chamber at the bottom.

- As the wood burns in the furnace, combustible gases are gradually produced. These gases are circulated and heated in the perforated ducts, eliminating the need for additional fuel when the fuel burns out.

- Observe the ducts in the combustion chamber. When the holes in the pipes are no longer on fire, the combustible gases have burned out and charring is complete.

- Operate the hanger to take out the inner furnace of the charring furnace and put it aside, then send another inner furnace filled with materials into the hoisting carbonization furnace, add fuel and start a new round of carbonization.

Temperature Control Process of the Vertical Carbonization Furnace

- Before 90°C: Use waste materials to start the fire and provide heat with a strong flame.

- At 90°C: Reduce the fire intensity.

- From 90°C to 150°C – Moisture Removal Stage: Begin the drying process to remove moisture from the wood sticks; maintain a gentle fire.

- At 150°C: Continue moisture removal for about 6 hours, increasing the fire intensity gradually.

- At 230°C – Combustion Support Stage: The furnace starts to produce mixed combustible gases.

- At 280°C – Self-Combustion Stage: The furnace generates carbon monoxide gas, which circulates and burns automatically. No external fire is needed. Close the bottom door of the furnace.

- During Heating Up to 280°C: The bottom door can be left open or closed as needed.

- Maximum Temperature: The internal temperature can reach up to 500°C.

- Best Carbonization Effect: For optimal results, maintain combustion for about 14 hours, followed by cooling for over 10 hours.

Video of charcoal making kiln working process

Hoisting charcoal maker for sale

| Model | SL-C1500 |

| Dimension | 1940mm*1900mm*1900mm |

| Inner tank size | 1500mm*1500mm |

| Outer bladder thickness | 6mm |

| Output capacity | 2500-3000kg/24 hours |

| Loading capacity | 2600-3000kg/per 8 hours |

| Weight | 2.8t |

| Including parts | One machine includes 3 stoves |

| Electricity Power | No need additional power |

| Biomass cost for heating per 8 hours | 50-80kg waste biomass per 8 hours |

Advantages of hoisting carbonization furnace

- The charring process and operation method of the hanger charring furnace are very simple, and the operator can work after simple training.

- The hanger has good bearing capacity, with a load of more than 2 tons, and the furnace body has no wearing parts and a long service life.

- The combustible gas produced can be recycled, so there is no need to add fuel all the time and save fuel cost.

- The lifting type charring furnace covers a small area and the inner tank is lifted by the remote control system. It is safe and convenient to operate.

- The vertical carbonization furnace is equipped with a flue gas purification system, and the flue gas emission is not polluting the environment.

Delivery of vertical carbonization machine worldwide